With the engine now running and the car able to move under it’s own steam it is time to make sure it can also stop again. So I have turned my attention to overhauling the braking system, starting with the front calipers.

Under first inspection the calipers were rather dry and crusty and full of crud, there was all sorts of detritus stuck in with the pads and the brake discs had a fairly heavy layer of surface rust. It was going to need more than a hose down, so off they came.

I decided to give the calipers a full strip down and let them soak in vinegar to clean them up. It is not a quick way to break clean away rust but I knew it would be a few weeks before I had time to do any more so leaving them to bathe for while was the easy solution.

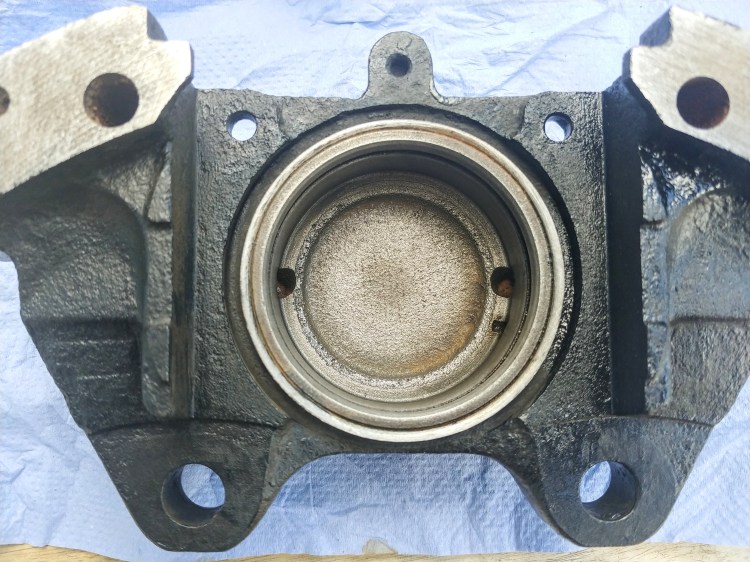

When stripping down the calipers the pistons came out easily by hand and were in good condition with no signs of rust or pitting. It seems like they were actually in good working order, nowhere near as bad as I thought and just needed a good clean up, but they were already in pieces so in for a penny, in for a pound.

After about three weeks a thick rust coloured crust had formed, a good sign that it was working.

After a quick wash down the caliper bodies were back to bare metal and looking as good as new!

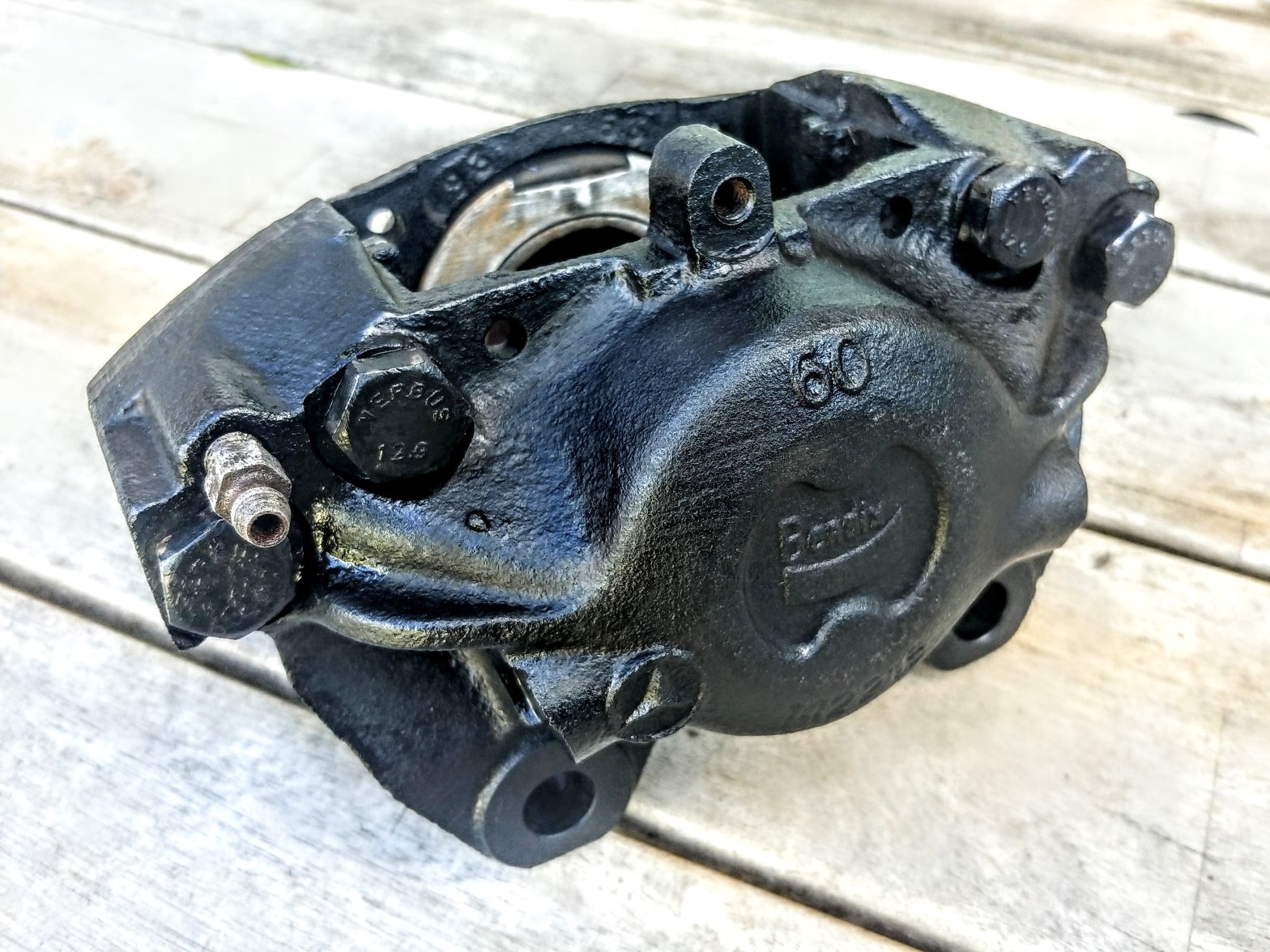

A lick of high temperature paint later and reassembly and they look just as good as they would have 40 years ago.

The next job was to clean up the brake discs. A length of threaded stud, some tub and nuts came together to make a nifty little handle that I could screw into one of the wheel bolt holes and use to spin the discs. Then is was just a simple case of holding some emery paper to the discs while turning. Job done.

Having stripped down this much, it made sense to go a bit further so off came the hubs. Everything was cleaned up with a wire brush and painted with hammerite. The old grease was flushed out of the wheel bearings which were then re-packed before the whole lot was reassembled.

Finally it was time to re-fit the callipers along with new flexible hoses of course.

The passenger side was straight forward, but on the drivers side nut of the rigid line was well seized into the flexi-pipe. I made a right meal of it and rounded the nut to the point it could never be reuses, so at that point it was time to resort to power tools to cut through the nut. Fortunately this pipe is short and easy to install so a new one wasn’t going to be the end of the world.

I tried to cheat by using a pre-made brake line, but the one I was sent was far too long and needed to be cut down to length anyway, so not quite as straight forward as I had hoped.

Below the old and the new. I deliberately left the new line longer so that I could trim it in situ and without the flare and nut it would pass through the original grommet in the engine bay without damaging it.

And there we have it, the new brake line in place, connected up to the new flexible hose and the refurbished caliper. This was my first time flaring a pipe so I will be sure to check this connection thoroughly for leaks when I come to bleed the system, but I am happy with how it is all coming along.

And finally, the car back down on all four wheels for the first time in months. Not that it will last long, time to move onto the rear brakes next!

If you want to see more progress updates, don’t forget to subscribe!